Services

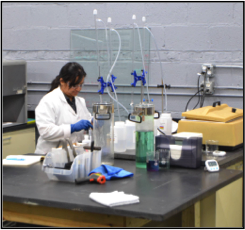

Techevon LLC offers complete and thorough lab analysis for our customers. Samples are processed quickly and accurately with complete paperwork for accurate records.

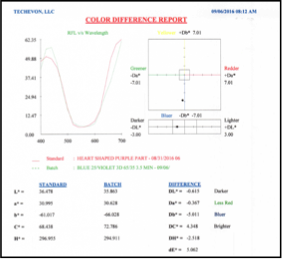

Color Matching

- We provide color-matching support using actual coupon dyeing guided by computer analysis using L/a/b values and a spectrophotometer curve.

- Coupons are prepared and returned to the customer. Single component dyes are used whenever possible to maximize color reproducibility.

|

|

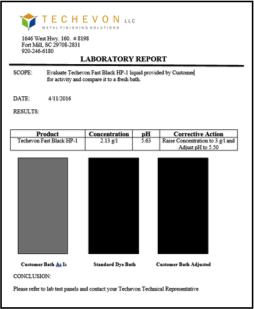

Chemical/Dye Bath Analysis

- Dye samples are compared against lab standards with actual coupon dyeing. A spectrophotometer curve is generated to evaluate bath performance.When required, the customer sample is then decanted and fresh dye added back in order to evaluate bath correction. Final recommendations are provided based on these tests.

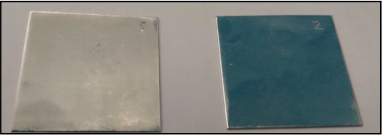

- Customer non dye bath samples are received and evaluated for performance. Test panels are used to compare customer chemistry against fresh chemistry for correct function to standard.

|

|

Process Evaluation/Development & Trouble Shooting

- We have a complete pilot anodizing line for conventional and hard coat capabilities in addition to multiple R&D process tanks. We can process Inorganic two-step coloring and organic dyeing along with several other finishes. The pilot anodizing line and R&D tanks allows us to experiment with process and procedures to troubleshoot customer problems as well as fully evaluate new process ideas.

- Lab analyses of current anodizing process performance can indicate opportunities to improve efficiency and develop additional anodizing capabilities using Techevon products.

|

|

|

Anodic Coating Testing

- Understanding coating thickness and density is vital to determine the durability and overall quality of an anodized surface.

- With our Anodic coating testing services we can provide coating weight and coating thickness details on a customer part to understand if it will meet various industry specifications include which include ASTM B 244-79, ASTM B 487-85, ASTM B 137-89, MIL 8625F and various AMAA specs.

|

|

|

Seal Quality Testing

- Seal Quality is a critical factor when assessing the quality of anodized parts. We provide several testing protocols that meet various industry applications and specifications.

- These specifications include Acid Dissolution ASTM B 136-84, ASTM B680, ISO 3210, and Modified Dye Stain ASTM B 136.

|

|

|

Corrosion Testing

- Determining the causes of corrosion and other surface defects on anodized parts can be critical to improving the production process.

- At Techevon we offer several corrosion testing services to understand the root causes of these surface defects and help troubleshoot customer issues.

|

|

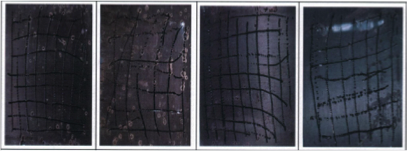

Taber Abrasion Testing

- Our Taber Abrasion testing service can be used to assess anodic coating surface wear resistance particularly for type III anodizing

- The test specification can cover the following ASTM D4060, ASTM D4060, Ford BN 108-02, Ford BN 108-04, MIL-STD-13231 Section 6.7, Freightliner 49-00023 Sections 7.12, PACCAR CMT 0033 Section 9.27, 9.28

|

|

Heat Fastness Testing

- Thermal shock is a critical factor that can affect the anodic coating. Therefore Heat Fastness testing can be used to determine the durability of a part in several applications that include industrial, architectural, medical and defense.

- Our testing specification can cover the AAMA 800 requirements. Furthermore we can test anodic coating tolerance to temperatures as high as 500°F / 260°C.

|

|

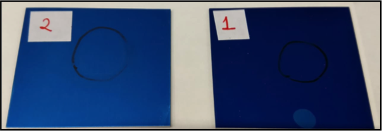

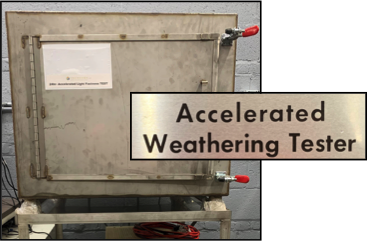

24hr Accelerated Lightfastness Testing

- We have developed an accelerated lightfastness test which in 24 hours can represent 8 years of outdoor exposure for an anodized coating. This tests incorporates both the effects of UV light and heat on an anodizing part to determine how it’s color may change over 8 years.

- Additionally this test correlates to conventional 2500 hr UV testing. 1 hour in our testing chamber represents 15 hours of QUV testing.

|

|

Custom Services:

Any special requests for unusual lab work or extensive projects can be made to techsupport@techevon.com